Basically, you have the choice between two ventilation principles in pig farming: natural and mechanical. One advantage of natural ventilation is the low investment due to the use of natural resources and simple installation. Systems based on natural ventilation have, however, become less popular due to the disadvantages of manual control and limited capacity. The required air exchange or temperature change is not always sufficient with natural ventilation. This can be regulated much more accurately and easily with the help of mechanical ventilation. In practice, natural and mechanical ventilation are sometimes used together: the hybrid system.

Mechanical ventilation comes in many forms. Below is a brief description of some common systems:

- Door ventilation

- ceiling ventilation

- valve ventilation

- combination ventilation

- Duct ventilation

- The fresh nose system.

Door ventilation (or feed corridor ventilation)

With door or feed corridor ventilation, the cold air enters the area at a low height and spreads towards the pigs over the partition. Such ventilation cannot be used in barns without separate areas. This system is applied to piglets and fattening pigs. Because the cold air is heavier than the barn air, this air stays more at the bottom. During cold spells, this sometimes results in lower temperatures and slightly higher air speed at the animals' berths.

Ceiling ventilation

With ceiling ventilation, the incoming air is mixed with barn air before it reaches the pigs. The air often passes through a layer of glass or rock wool first. As a result, the air has a very low speed. The disadvantage is that the wool can clog up with dust. That is why air filters are often positioned at the inlet. Ceiling ventilation is suitable for piglets, because draft is almost impossible.

Valve ventilation

With valve ventilation, the air inlet with an adjustable valve is placed at the top of the side wall (s). During winter, there is a risk of discomfort as a result of cold air on the pigs. This system is therefore less suitable for a farrowing pen or fattening pig barn.

Combination ventilation

Combination ventilation combines ceiling and door ventilation. This system has a false ceiling (without openings). A gap is made in the ceiling above the feed corridor so that the fresh air falls into the feed corridor and not directly onto the pigs.

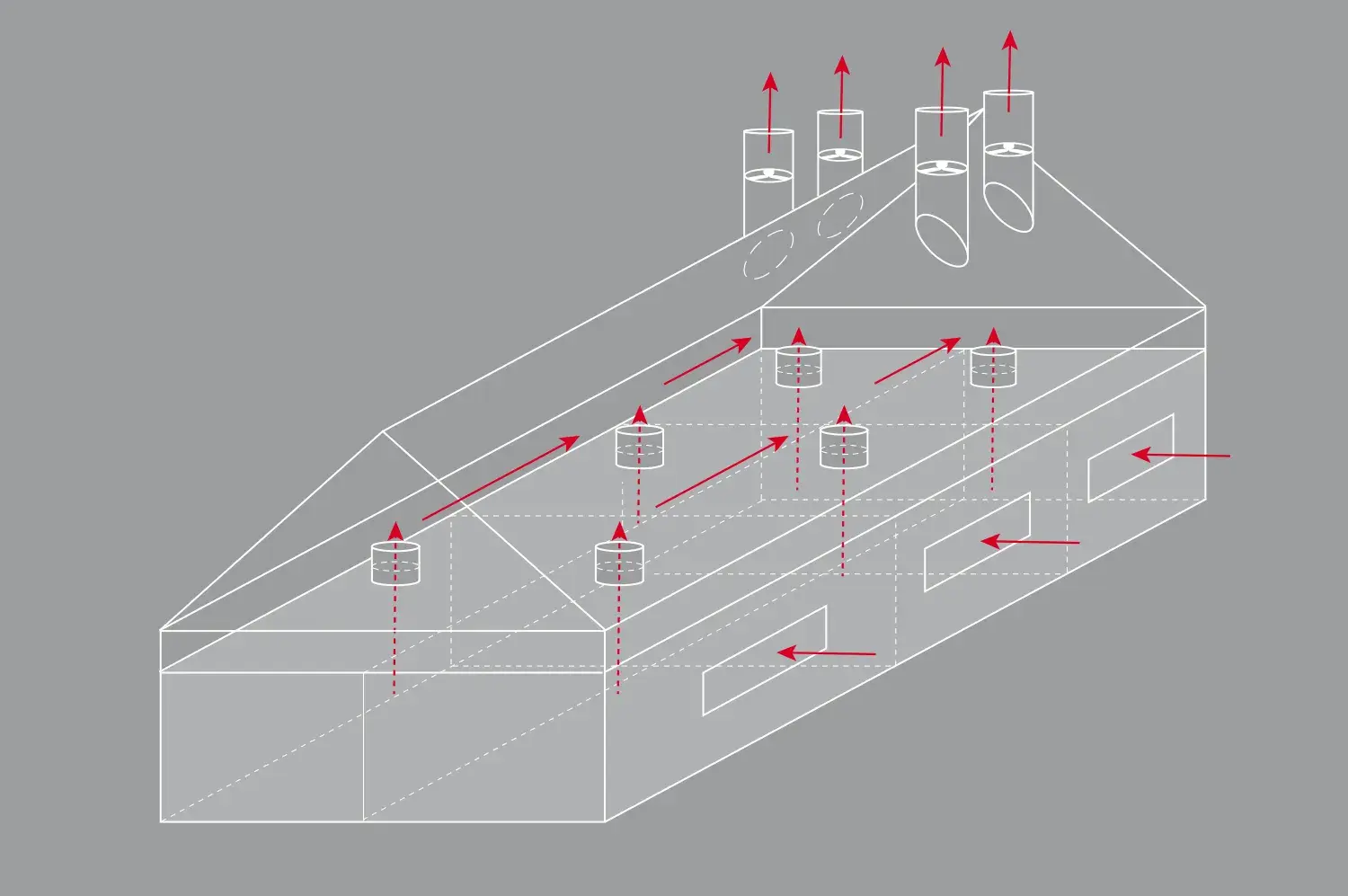

Duct Ventilation

With duct ventilation, the air enters through a duct below the feed corridor. The air distribution is good. In addition, this system has little risk of drafts.

'Fresh nose' system

The 'fresh nose' system, or tube ventilation, is often used in farrowing pens. Fresh air is brought (via a tube above the trough) to the head of the sow on the wall side. The piglets are on the other side.

Central exhaust system

The name of the system says it all: with central extraction, the air from the entire pig barn is brought together in a central air duct in order to leave the barn at one point. A central exhaust system is often combined with an air washer.

Also read: The pros and cons of central exhaust systems in pig barns

Fans

When choosing the type of fans used in pig barns, i.e. the 'hardware' of the ventilation system, it is important to consider the following:

- The durability and reliability of the fans

- The suitability for intensive use

- The controllability

- The resistance to aggressive conditions