For decades, our Multifan, EMI and Mf-Flex motors have been known as very robust and reliable. The motors proven concept has remained unchanged over the years; while its configurations have been further refined to keep up with energy efficiency guidelines. But what is it exactly, that makes our motors so special?

Developed for the agricultural market

Since its foundation in 1952, Vostermans Ventilation has undergone considerable changes. Founder Toon Vostermans started his ventilation factory locally, focusing on applications for the Dutch agricultural areas. Vostermans quickly became a specialist in this developing sector, and the fans were attuned to the demands of the market. The specialization in this sector, and the robust products it required, are still part of our product portfolio, almost 70 years later.

No compromises on quality

We understand that ventilation in the agricultural sector is essential for animal welfare. This is why we cannot afford to compromise on the quality of motors. We opt for the best bearings suitable for ammonia-rich, moist and warm environments, and utilize copper wire with extra protective layers. Although unnecessarily robust in many cases, it is necessary in some settings. Quality materials and solutions allow our motors to meet even the strictest certifications, such as UL and CSA, and to comply with insulation class F.

A Dutch heart

Vostermans motors are developed and produced in the Netherlands. Our R&D team is continuously working on development and production is constantly being expanded and upgraded. In this way, we create the means to further reduce tolerances and continuously improve the efficiency of the motors. As a result, our motors are among the best on the market.

An open motor

Our motors are IP55 certified, which means that it is impossible for large amounts of spray water or dust to enter the motor. Because of condensation alone, however, about 0.5 liters of water flows through the motors annually. It is therefore essential that moist air can escape the motor. We have developed special drainage channels for this purpose, extending the service life of our motors considerably.

Customization is the standard

Vostermans differentiates itself from competitors by offering customization of motor-impeller combinations, allowing for hundreds of made-to-fit solutions. Balanced motor-impeller solutions create greater fan efficiency and a reduced motor load, extending service life. In addition, it ensures that most standard motors can withstand 10% overvoltage and 20% under voltage. This prevents failures in areas where power grid fluctuations are common.

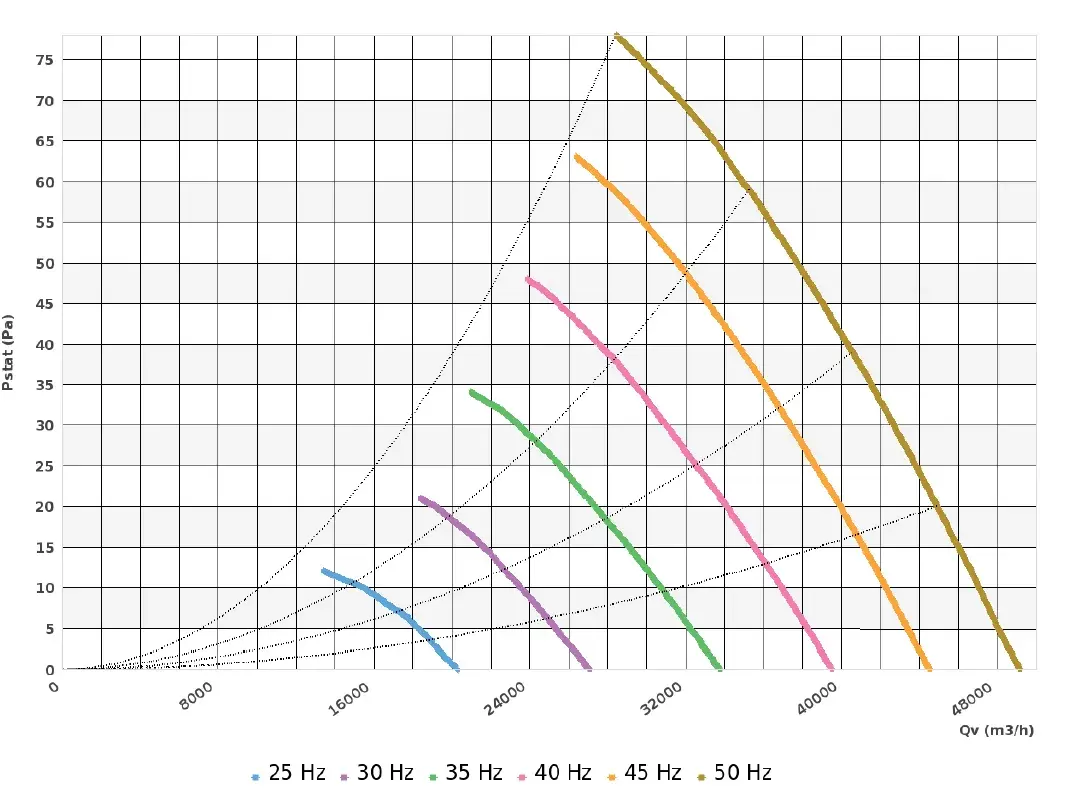

The right data with practical applications in mind

Where suppliers of other motors often only show data from separate motors, we always show the performance of motors in combination with impellers. We acquire the required measurement data using our motor test bench and our advanced wind tunnel. Based on the performed tests, we deliver the optimal combination that matches the practical demand, and we show results that are realistic in practical applications.

Optimal service

As we develop and produce motors ourselves, we are able to offer extensive services. This includes repairing motors, supplying alternative products and sending parts. In addition, as a standard policy, we provide a 3-year warranty on our Multifan, Mf-Flex and EMI motors.

Related topic: Vostermans service