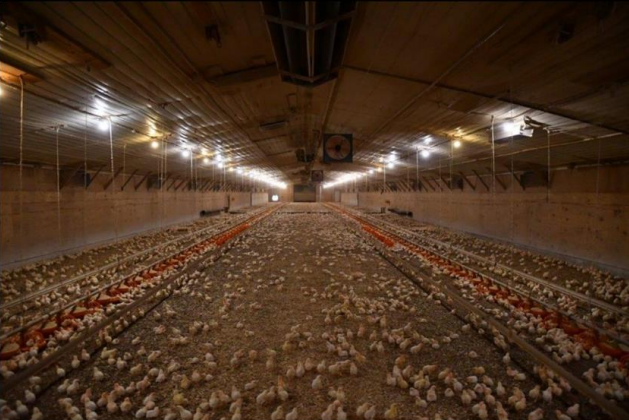

Good ventilation in poultry barns ensures optimal temperature and air quality at the animal level. The distribution of air and the air pattern (how the air enters the barn, spreads out, and mixes) are crucial for this.

When airflow and air patterns are arranged properly, poultry can perform optimally. Diseases and issues such as respiratory problems, slowed growth, foot sole and heel issues, soiling, and higher dropout rates can be avoided.

Temperature

“Good ventilation has to be beneficial to the animals and suited to their needs (and not ours). The biggest misconception, I think, is that poultry farmers often think it has to be cool in the barn. Because of this, they then ventilate as much as possible. However, cool often means cold. When caretakers find the climate pleasant, this doesn’t mean that chickens (especially chicks) also find it pleasant,” says Mr. Henk Rodenboog, climate specialist and zoo technician at De Heus Voeders B.V.

Mature animals feel comfortable between 20 and 27 degrees Celsius, but young animals experience comfort between 30 and 35 degrees. In such cases, the rule is: when we find it pleasant, it is too cold for the animals. Both cold/draft and heat are disastrous for optimal performance (see our article on the relevance of a comfortable climate in poultry barns).

“A big additional misconception is that thermometers always indicate the right temperature. Sometimes they indeed do, but there is no existing thermometer that also includes wind speed to display the true apparent temperature. Often, animals experience temperatures as colder than expected based on the measured temperature. Simultaneously, this offers us many opportunities during very warm summers. Then, animals can stay in their comfort zones longer than caretakers expect. By using wind speed to repeatedly drive away heat from the skin of the animals, we can give them the sense that it is colder than it is in reality,” adds Mr. Henk Rodenboog.

Minimum and Maximum Ventilation

The minimum ventilation has to be sufficient. With the comfort zone of the animals, the ventilation amount must be increased to disperse extra heat until the maximum ventilation is reached.

Related topic: Understanding minimum ventilation in poultry barns.

Henk Rodenboog: “For a long time, we assumed a maximum ventilation of 4 m3 airflow per kg of live weight in the barn. Because we nowadays have more peak days with hot temperatures, most poultry farmers like to have some extras at hand to use in those cases. The settings between minimum and maximum ventilation are quite critical and have to be precise. Besides refreshing the right amount of air, it is equally important to properly utilize the refreshed air. Placement of, and the number of inlet valves are just as important for good ventilation.”

Fans and Maintenance

Concerning ventilation, a good barn climate for optimal animal performance is not the only aspect for good operational results. The investment and costs of the ventilation system are also important for efficiency and must be manageable. This applies to both the initial investment and the energy consumption and maintenance costs.

Poorly maintained and dirty fans have higher energy consumption and quickly lose flow rate (the amount of air being moved). Because of this, make sure to pay attention to the following for your poultry barn:

- Durability and reliability: Choose fans that last long and consistently perform well, even under prolonged use.

- Suitability for intensive use: Fans should withstand the heavy demands of continuous operation in a livestock environment.

- Resistance to aggressive and corrosive conditions: Fans in poultry barns are often exposed to dust, moisture, and ammonia. Ensure the equipment is built to withstand these conditions.

- Performance at negative pressure: Fans must continue to operate effectively even when there is negative pressure in the barn, ensuring a consistent and reliable airflow.

De Heus is an internationally operating organization specializing in producing and marketing high-quality animal feed.