Basically, you have the choice between two ventilation principles in poultry farming: natural and mechanical.

Natural ventilation

One advantage of natural ventilation is the low investment due to the use of natural resources and simple installation. Natural ventilation is based on the chimney effect. Warm air rises and disappears through an opening in the roof ("chimney"). This creates a slight negative pressure in the stable and fresh air is sucked in through inlet openings on the side (those with flaps or curtains opened or closed). Systems based on natural ventilation have, however, become less popular due to the disadvantages of manual control and limited capacity.

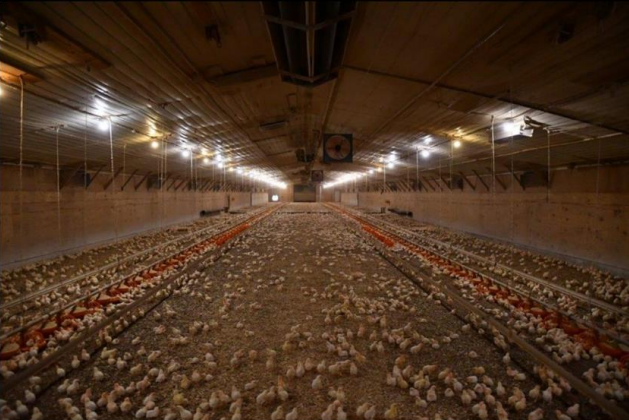

Mechanical ventilation

The required air exchange or temperature change is not always sufficient with natural ventilation. This can be regulated much more accurately and easily with the help of mechanical ventilation. Fans provide much more certainty about the amount of displaced air.

With mechanical ventilation, the air can be extracted by fans, blown in, or a combination of both. In those cases, we speak of ventilation on negative pressure, positive pressure or equal pressure.

“Ventilation based on negative pressure is by far the most common. But with all sorts of alternative housing systems, in which the chickens regularly have to go outside, the demand for other ventilation systems is also increasing, in particular the demand for equal pressure ventilation. With this system, direct flow over the animals through the hatches is prevented.

"Many poultry farmers find this system too expensive, because you need both extraction and blow-in fans, which together also consume much more electricity. "

Nevertheless, it is expected that this will be applied more in the future, provided that it fits in with legislation and regulations." Mr. Henk Rodenboog, Climate Specialist and Zoo Technician at De Heus Voeders BV*.

Mechanical ventilation for poultry barns is available in a variety of forms. Below is a brief description of some common systems: ridge ventilation, length ventilation, tunnel ventilation and cross ventilation. Combinations of these systems are also possible, such as length and ridge ventilation, or length and tunnel ventilation.

Ridge ventilation

With ridge ventilation, the fans are mounted in ducts that are placed in the ridge of the roof. The air inlets are then incorporated in the side walls. Ridge ventilation is generally only used for minimum ventilation.

Length ventilation

With length ventilation, the fans are in the end wall and the air inlets in the side walls. By further increasing or decreasing the speed of fans and opening or closing the air inlets, a wide range of air exchange is possible.

Tunnel ventilation

For maximum ventilation, tunnel ventilation is often used where the inlets are mounted in the end façade and the fans in the opposite end façade. This makes it possible to blow the air through the house at high speed during very hot days. The high speed provides a wind chill effect, which gives the chickens a pleasant-feeling temperature.

Cross ventilation

For cross ventilation, the fans are placed in a side wall. The inlets are positioned in the opposite side wall. Because the distance from inlet to fan is short, it becomes possible to exchange the air in a house at a very low speed. This system is suitable for moving both a little and a lot of air.

Fans

When choosing the type of fans used in poultry houses, i.e. the ‘hardware’ of the ventilation system, it is important to consider the following:

- the durability and reliability of the fans

- the suitability for intensive use

- the controllability

- the resistance to aggressive conditions

For a visual example of the different ventilation systems watch the video below and see the effect of the various systems on the air movement in the barn.