Minimum ventilation is necessary to ensure a sufficient amount of oxygen in the barn and to remove hazardous substances. For this reason, it is important that the minimum velocity settings are correct. In this blog, we explain how you can ensure minimum ventilation in the two most common systems.

We use the "fan laws" as the basis for our explanations. Depending on the ventilation system, you can save a lot of energy by following these rules and using a frequency drive.

Below we explain the two most common systems:

Ventilation system without controlled inlets

This is a tunnel ventilation system - without controlled inlets, and with a static pressure that changes depending on the air flow.

This means that the highest static pressure (∆Pstat) is as high as the maximum air flow. The pressure decreases as the square of the air flow.

For example: The airflow at maximum ventilation is 100% and the static pressure (∆Pstat) is 30 Pascal (total resistance from input, friction on walls and surfaces, cooling, light locks, etc.).

If the amount of air flow is reduced to 20% (at night, due to falling temperatures), the total static pressure ∆Pstat drops to (20/100) ^2 *30Pa = 1.2Pa.

This means that the new air curve must reach at least 1.2Pa at the lower speed. For safety reasons, we recommend using the speed at which the fan curve reaches at least 20 Pa (in our graph the line 30Hz).

Controlled ventilation system

Buildings with controlled air inlets. In such buildings, ∆Pstat is constant at a certain level. When the demand for air falls, the inlet openings become smaller in order to keep the inlet velocity and thus ∆Pstat constant.

For example: The maximum air flow is 100% and the inlets ensure a static pressure of 20Pa in the building (adjustable via computer setup).

During the night, the temperature drops and the animals only require 30% of the air volume.

The inlet opening is reduced in accordance with the lower air volume and the fan slows down until ∆Pstat is at 20Pa.

This means that you can use the curves that reach 20Pa. We recommend an additional 10Pa to ensure that the volume is sufficient. In this case, use the curve that reaches 30Pa (in our graph the line 35Hz).

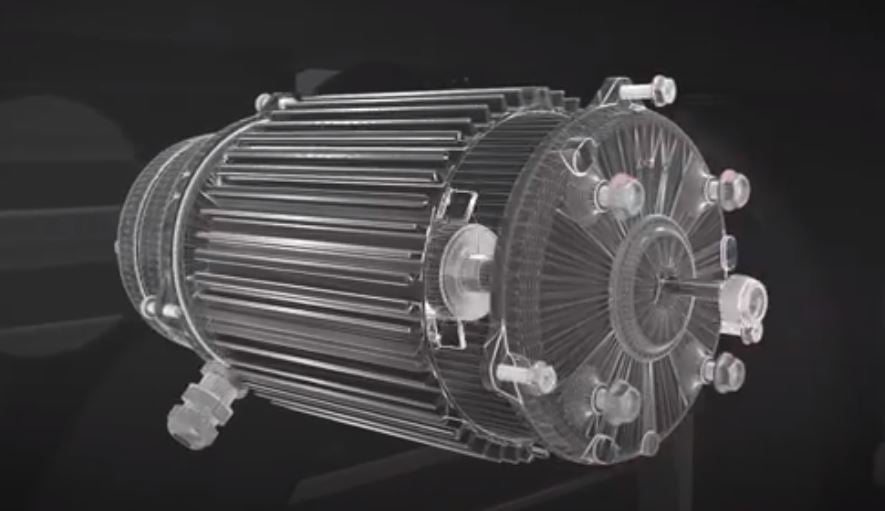

Our axial blowers are extensively tested. That's why we know exactly how they perform. This way you can easily find out which fan is suitable for your situation. You can find our range of exhaust fans here.