Usually, fans in greenhouses are not regulated. The main reason is that lowering the speed negatively affects the fan's throw and circulation rate. This can result in reduced circulation efficiency and an increased risk of climate issues. Nevertheless, in practice, we sometimes see customers opting for speed controllers. Most often, this is to reduce fan noise, and occasionally to save energy.

Reducing speed without adverse consequences

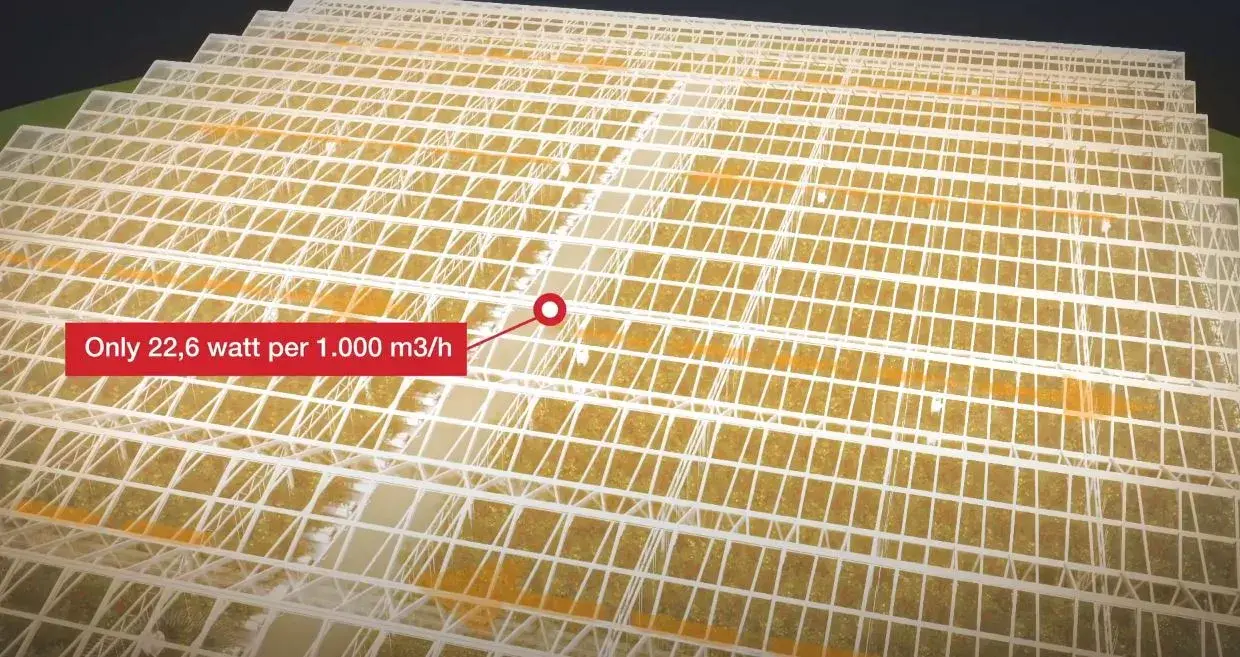

One m³ (35 ft³) of air weighs approximately 1.2 kg (2.6 lbs) at a temperature of 20°C (68°F). This means a fan with a capacity of 5,000 m³/h (3,000 CFM) moves 6,000 kg (13,228 lbs) of air per hour. This explains why it takes some time before all the air in the greenhouse is set in motion. Once the air is moving, however, this mass helps ensure it does not easily come to a standstill again. In practice, we observe situations where fans run at 100% speed for 2 to 3 hours before being dialed back to around 70% speed. This is typically sufficient to maintain airflow.

Saving energy

Reducing fan speed can save energy, depending on the type of fan controller used. The energy-saving benefits are greatest with frequency inverters, moderate with transformers, and least with triac inverters. However, there are significant differences in purchase prices and installation costs. We are happy to assist you in finding the best solution for your needs.

See our range of controllers here

Noise reduction

We have significantly reduced the noise of the new generation of Multifan Greenhouse Fans. The most energy-efficient 5,000 m³/h (3,000 CFM) variants produce noise levels that barely exceed ambient noise. Therefore, it is unlikely these fans will need to be regulated down to reduce noise.